The pile direction in textiles plays a key role in how colors appear to you. When light hits the fabric, the way fibers are aligned can change its brightness, sheen, and perceived shade. Pile orientation can make colors look richer or duller and even cause subtle shifts in hue. By understanding how pile affects color perception, you can better choose and control fabric appearance—exploring these effects further helps you master the visual impact of textiles.

Key Takeaways

- Pile direction alters how light reflects off the fabric, influencing perceived color brightness and sheen.

- Fiber orientation affects dye absorption, causing subtle variations in fabric color depending on pile direction.

- Changing pile orientation can modify the apparent shade or depth of color due to light interaction differences.

- Pile alignment emphasizes or diminishes visual patterns, impacting the fabric’s overall color perception.

- Consistent pile direction ensures uniform light reflection and dye absorption, maintaining color consistency across the textile.

Understanding Pile Orientation in Textiles

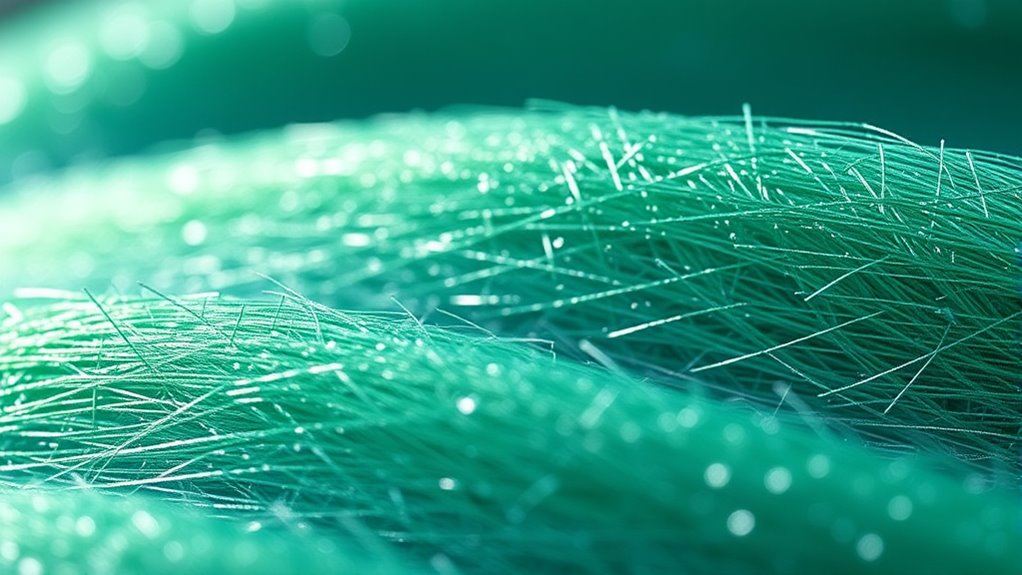

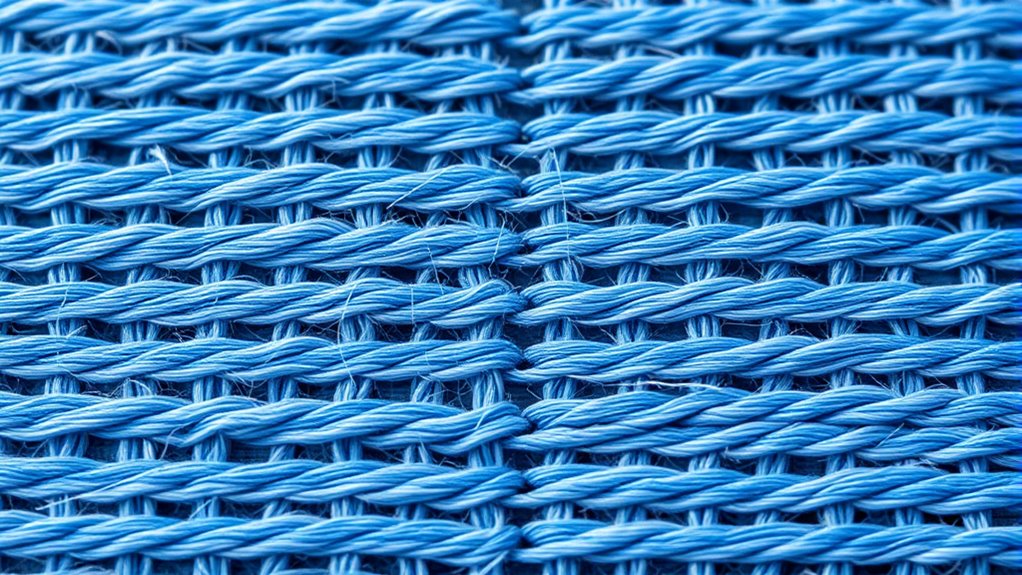

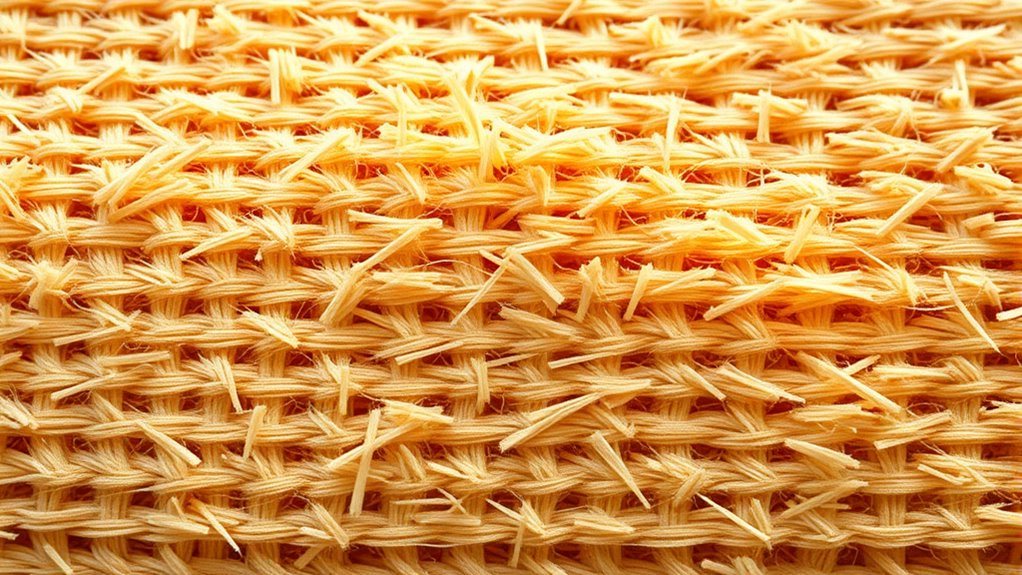

Understanding pile orientation in textiles is essential because it directly influences how the fabric looks and feels. When fibers are aligned consistently during manufacturing, the pile direction becomes uniform, resulting in a predictable appearance and tactile quality. Proper fiber alignment guarantees the pile faces in the same direction, which affects how light interacts with the fabric and how colors appear. Manufacturing consistency plays a vital role in achieving this uniformity, as inconsistent pile direction can create visual irregularities and uneven color reflections. By controlling fiber orientation during production, you can guarantee your textiles maintain a consistent look, enhance durability, and achieve the desired aesthetic. Mastering pile orientation helps you produce fabrics with precise color effects and a professional finish. Additionally, understanding fiber orientation is crucial for selecting textiles that will age well and resist fading over time, especially since material consistency impacts color stability and longevity. Ensuring manufacturing precision can significantly reduce variations in pile direction, leading to more uniform color appearance and higher quality products.

How Pile Direction Influences Light Reflection and Color

The direction of the pile considerably affects how light reflects off the fabric, which in turn influences its apparent color. When the pile runs in one direction, the fiber texture interacts with light differently than when it’s reversed, creating variations in reflection. This change impacts how your eyes perceive color, making it appear brighter or duller depending on the angle. Pile direction also influences dye absorption; fibers aligned in a specific way absorb dye more uniformly, resulting in consistent color. Conversely, fibers oriented differently might reflect light unevenly, causing subtle shifts in hue or sheen. Understanding this relationship helps you control the visual effects of your textiles, ensuring the color and texture you want are properly showcased by the way light plays on the pile. Additionally, awareness of AI safety measures in textile production can help prevent unintended outcomes in manufacturing processes. Recognizing the importance of fiber orientation can further enhance the desired visual effects and durability of the finished textile. Being mindful of light reflection dynamics also allows for better customization of fabric appearance under different lighting conditions, and considering material properties can optimize the overall aesthetic and longevity of the textile.

Visual Effects of Pile Arrangement in Fabric Design

The arrangement of the pile deeply influences the visual effects of fabric design, shaping how patterns and textures are perceived. When pile fibers are aligned in specific directions, they create varying fiber textures that catch light differently, enhancing or diminishing certain visual aspects. Pile arrangement also affects dye penetration; fibers aligned uniformly allow dye to settle evenly, producing consistent color, while irregular directions can cause color shading or unevenness. This interplay influences the fabric’s overall appearance, making certain patterns stand out or blend in based on pile orientation. By controlling the pile’s direction, you can emphasize textures and create visual depth, adding richness to the design. Additionally, understanding how fiber texture and dye penetration interact with pile arrangement helps you craft fabrics with intentional, striking visual effects. The natural materials used in Waldorf toys further demonstrate the importance of tactile and visual harmony, enhancing sensory experiences and aesthetic appeal.

Techniques for Assessing Pile Direction in Production

To accurately assess pile direction in production, you need reliable techniques that enable you to identify fiber alignment quickly and consistently. One effective method is examining fiber alignment through visual inspection, looking for subtle differences in the way light reflects off the surface. Additionally, dye penetration tests can reveal fiber orientation; when dye is applied, it penetrates more readily along the grain, highlighting the pile’s direction. Using a magnifying glass or microscope helps you observe these details with precision. Proper fiber alignment ensures better overall fabric quality and performance. To further improve accuracy, conducting fiber orientation tests helps confirm the visual assessments and maintains consistency across batches. Incorporating vibrational state assessments can also contribute to understanding how the fibers are aligned at a microscopic level, further enhancing quality control. Recognizing the influence of pile direction on light reflection and color appearance allows for more accurate evaluations. By mastering fiber alignment assessment and dye penetration, you gain better control over production quality.

Practical Strategies for Managing Pile-Related Color Variations

Mastering fiber alignment techniques helps you identify and control pile direction, but managing color variations caused by pile differences requires targeted strategies. To minimize inconsistencies, focus on controlling dye absorption by ensuring uniform fiber alignment during manufacturing. You can also:

- Use consistent fiber types and dyeing processes to promote even dye uptake

- Rotate batches or blend fibers from different production runs for uniformity

- Adjust dyeing parameters, like temperature and pH, to improve dye absorption consistency

- Conduct color matching tests on samples before full production runs

- Implement color matching techniques to further ensure uniformity across batches

- Rely on quality control measures throughout the production process to detect and correct deviations early

- Emphasize fiber consistency to prevent unwanted color shifts caused by pile direction changes. Adopting standardized procedures can further reduce variability caused by pile-related factors. These approaches help mitigate color shifts related to pile direction, ensuring a more uniform appearance. Implementing precise fiber alignment and dyeing controls reduces the impact of pile-related color variations, giving you a more predictable, high-quality product.

Case Studies Demonstrating Pile Direction Impact on Color Perception

Real-world examples reveal how pile direction can markedly influence color perception in fabrics. In one case, a velvet curtain’s fiber alignment caused a noticeable shift in hue depending on the pile’s orientation. When the pile was aligned in the direction of dye penetration, the fabric appeared richer and more uniform. Conversely, when viewed against the pile direction, color intensity diminished, revealing uneven dye absorption. Another example involves a plush upholstery fabric, where the pile’s direction affected light reflection, altering perceived shade. Fiber alignment plays a crucial role in how dyes interact with fibers, directly impacting color consistency. These case studies highlight that fiber alignment determines how dye penetrates the fibers, directly impacting color consistency. Recognizing how pile direction influences dye penetration allows you to make better decisions during manufacturing, ensuring the final product meets your desired color standards. Additionally, understanding the automation in business can streamline production processes, further ensuring consistent dye application and color outcomes, especially when combined with precise control over color management systems. Proper consideration of dye absorption is essential for achieving uniform color results in textile production.

Frequently Asked Questions

How Does Pile Direction Affect the Durability of Fabric Colors Over Time?

Pile direction influences fabric color durability by affecting fiber distortion and dye migration. When fibers are aligned consistently, dye stays evenly fixed, reducing fading over time. Inconsistent pile directions can cause uneven dye migration, leading to color loss or uneven fading. By maintaining proper pile direction during manufacturing, you can guarantee your fabric’s colors stay vibrant longer, as it minimizes fiber distortion and prevents dye from migrating unevenly.

Can Changing Pile Orientation Alter the Perceived Texture of the Textile?

Imagine your textile as a dance of fiber illusion, where every step shifts the scene. Changing pile orientation acts as a choreographer, creating optical variation that can dramatically alter the perceived texture. When you adjust the pile, it’s like flipping a switch, revealing a new layer of tactile depth. This subtle shift transforms the fabric’s feel, making it seem softer, rougher, or more plush — a visual and sensory metamorphosis.

Are There Specific Fibers More Sensitive to Pile Direction in Color Perception?

You might notice that fiber sensitivity to dye absorption varies, affecting how color appears based on pile direction. Natural fibers like wool and silk tend to be more sensitive, showing noticeable color shifts with pile orientation changes. Synthetic fibers such as polyester are less responsive. Understanding these differences helps you predict how changing pile direction could influence the perceived color, especially with fibers that exhibit higher dye absorption and sensitivity to fiber orientation.

How Do Environmental Factors Influence the Impact of Pile Direction on Color?

Did you know that environmental factors can change how pile direction affects color? You’ll notice that light reflection varies with surroundings, making colors appear more vibrant or muted. Humidity, lighting, and even viewing angle influence color saturation, especially when pile direction shifts. This means your carpet’s appearance isn’t just about its fibers but also how environmental conditions interact with light and pile orientation, creating dynamic color effects.

What Are the Latest Technological Advances for Controlling Pile Direction Consistency?

You should explore the latest technological advances like laser-guided systems and automated fiber alignment tools that help maintain consistent pile direction. These innovations improve fiber alignment accuracy, ensuring uniformity throughout production. They also optimize dye penetration, resulting in more consistent color appearance. By adopting these technologies, you can reduce variability, enhance quality control, and achieve reliable, high-quality carpet or textile products with precise pile direction control.

Conclusion

Think of pile direction as the compass guiding your fabric’s story, shaping how light dances and colors come alive. Just like a skilled sailor navigates with the stars, you can steer your textiles to achieve the perfect hue and texture. Mastering pile orientation is your map to consistent color perception, transforming each piece into a vibrant voyage. Embrace this guidance, and watch your fabrics tell their colorful journey with clarity and charm.