Higher knot density increases the manufacturing cost because it takes more skill and time to produce tightly woven fabric. This results in a higher price, but it also offers better durability and a luxurious feel. If you prioritize longevity and quality, paying more can be worthwhile. However, lower knot density fabrics can still be durable and comfort-focused. To understand how knot density impacts value fully, keep exploring the details below.

Key Takeaways

- Higher knot density increases manufacturing complexity, labor, and dyeing processes, which raises the fabric’s overall cost.

- Dense fabrics are more durable and longer-lasting, often justifying a higher price for quality-conscious buyers.

- Premium knot density enhances fabric feel and appearance, adding value for luxury or detailed applications.

- Investing in higher knot density may be worthwhile if durability, aesthetics, and longevity are priorities.

- For casual or less demanding uses, lower knot density offers affordability without significantly sacrificing quality.

Understanding Knot Density and Its Measurement

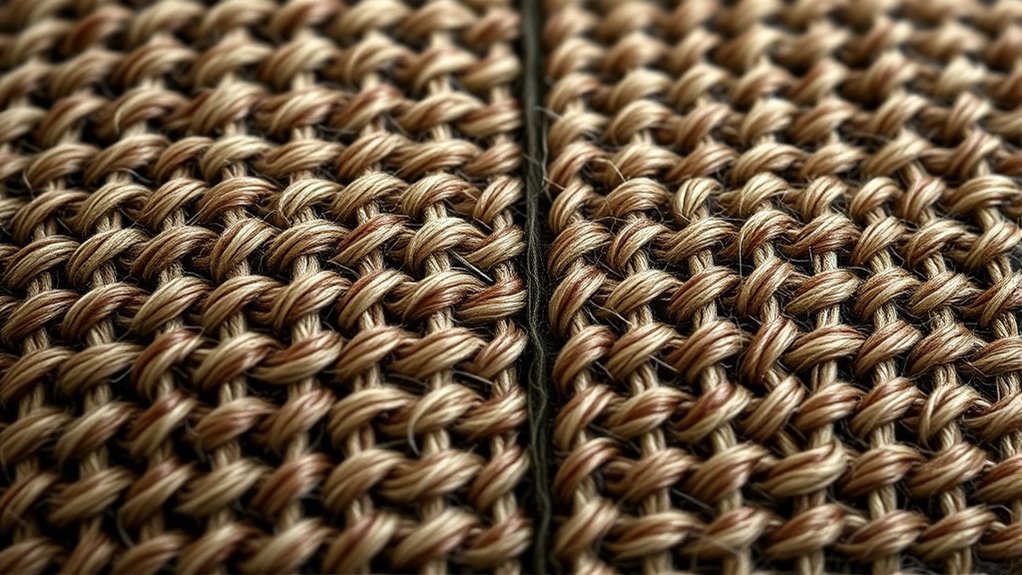

Understanding knot density begins with recognizing its importance in determining fabric quality and price. Knot density measures how tightly the knots are woven into the material, directly impacting durability and appearance. To accurately assess knot density, you need to take into account the material composition, as different fibers respond uniquely to weaving. Manufacturing techniques also play a vital role; skilled craftsmanship results in consistent, higher knot densities. Typically, manufacturers count the number of knots per square inch or centimeter, providing a standardized way to compare fabrics. Higher knot density usually indicates a more refined, durable fabric, though it can also mean increased production costs. Additionally, the fiber type used in weaving significantly influences knot density and overall fabric strength. By understanding these factors, you can better evaluate the true value of a textile and decide if it’s worth paying more for higher knot density.

How Knot Density Influences Material Durability and Feel

Higher knot density directly enhances a fabric’s durability by creating a more tightly woven surface that resists wear and tear over time. When a fabric has more knots per inch, it becomes sturdier and less prone to fraying or damage. This increased density also influences the feel, making the material feel firmer and more substantial under your touch. Different weaving techniques, such as tight hand-knotting or machine weaving, can achieve higher knot counts, further improving longevity. As the knot density rises, the fabric’s resistance to stretching and abrasion improves, extending its lifespan. Additionally, higher knot densities can provide better resistance to skin irritation, making the fabric more suitable for sensitive skin. You might notice that fabrics with higher knot densities feel more luxurious and durable, which is a direct result of the tighter weave and enhanced structural integrity. Moreover, fabrics with higher knot densities often require more precise craftsmanship, which can influence the overall price and perceived quality. Investing in higher knot density can also be viewed as an investment in quality, leading to greater satisfaction and long-term value.

The Relationship Between Knot Density and Price

Knot density considerably influences the price of fabric, as higher densities require more skilled craftsmanship and time-consuming weaving processes. Fabrics with increased knot density often use synthetic fibers, which can add to costs due to material quality and manufacturing complexity. Higher knot density typically results in a more durable and refined fabric, but it also means more labor and resources are involved. Additionally, knot density affects dye penetration; denser fabrics may resist dye, leading to more specialized dyeing techniques, which increase production costs. The fiber quality used in high-density fabrics also plays a significant role in their overall cost. Moreover, the weaving method employed can impact both the final price and the fabric’s overall appearance and durability. The manufacturing process for high-density fabrics often involves precise control and advanced machinery, further contributing to higher prices. For example, controlled tension during weaving ensures uniform knot density and fabric strength, adding to production complexity. Consequently, fabrics with higher knot densities tend to be more expensive, reflecting the effort and quality involved. If you’re considering price versus quality, understanding this relationship helps you decide whether paying more for a higher knot density is justified for your needs.

Factors to Consider When Choosing a Higher vs. Lower Knot Density

When choosing between higher and lower knot densities, you need to contemplate how the fabric’s intended use influences your decision. Knot density myths often lead buyers to believe that more knots always mean better quality, but that’s not necessarily true. For example, a higher knot density might be essential for detailed embroidery or intricate designs, especially in luxury or designer branding fabrics. However, for casual or everyday use, a lower knot density can still offer durability without the extra cost. Consider how you’ll use the fabric—if you need fine detail or a premium feel, leaning toward higher knot density makes sense. But if budget or comfort is your priority, lower knot density fabrics can provide good value without sacrificing performance. Additionally, understanding how knot density impacts fabric texture can help you make a more informed choice based on your specific needs. Moreover, evaluating how knot density affects durability and softness allows you to select the best option for longevity and comfort.

Tips for Assessing the Value of Knot Density in Your Purchase

To assess the value of knot density effectively, start by considering how the fabric’s intended use aligns with its knot count. Higher knot densities often indicate better fiber quality, which can enhance durability and overall feel. Penetration testing can reveal the fabric’s resilience to wear and tear, providing insight into its longevity. However, a higher knot density doesn’t always mean better aesthetic appeal; it depends on your style preferences. Examine the craftsmanship and fiber quality closely—look for tight, uniform knots and smooth progressions. If you’re after a luxurious look, a higher knot density might justify a higher price. Conversely, if you prioritize softness or a more casual appearance, lower densities could suffice. Additionally, understanding AI advancements in textile manufacturing can help you decide whether investing in higher quality is worth it for your personal or professional needs. Ultimately, weigh the fiber quality and aesthetic appeal against the cost to determine if paying more for a higher knot density offers real value for your specific needs.

Frequently Asked Questions

Does Higher Knot Density Always Mean Better Quality?

Higher knot density doesn’t always mean better quality. While it can indicate durability, other factors like synthetic fibers and dye stability matter more. Synthetic fibers can enhance strength, but if dye stability isn’t maintained, the rug’s appearance fades quickly. So, focus on the overall material quality and craftsmanship rather than knot density alone, ensuring your rug lasts and looks good over time.

How Does Knot Density Impact Rug Cleaning and Maintenance?

Like a double-edged sword, knot density influences rug cleaning and maintenance. Higher knot density makes your rug more durable, but it also means more delicate fibers that can trap dirt and require careful cleaning. You’ll need to vacuum thoroughly and occasionally get professional cleaning to preserve its beauty. While denser knots boost durability, they demand a little extra attention, ensuring your rug stays beautiful and functional for years to come.

Are There Specific Rug Styles That Benefit More From Higher Knot Density?

You’ll notice that luxury patterns and traditional designs often benefit more from higher knot density. This is because intricate details and fine craftsmanship are better preserved, resulting in sharper images and richer textures. If you love elaborate motifs or classic styles, investing in a rug with higher knot density can truly enhance its appearance and durability. So, if authenticity and detailed artistry matter to you, it’s worth paying extra for a higher knot density.

Can Knot Density Affect Allergy Risks or Indoor Air Quality?

They say, “You are what you breathe,” and knot density can influence allergen retention and fiber safety. Higher knot density often traps more dust, pollen, and allergens, potentially increasing allergy risks and affecting indoor air quality. If you’re sensitive, choose rugs with lower knot density or those made from hypoallergenic fibers. Always prioritize fiber safety to ensure your home remains a healthy space for everyone.

What Is the Typical Lifespan Difference Between Low and High Knot Density Rugs?

You’ll notice that high knot density rugs generally have better knot durability, which extends their rug longevity. These rugs are more tightly woven, making them more resistant to wear and tear over time. In contrast, low knot density rugs tend to wear out faster, often lasting 10-20 years. If you want a durable investment that maintains its appearance longer, spending more on a high knot density rug is usually worth it.

Conclusion

Ultimately, understanding knot density helps you make smarter choices and avoid paying for more than you need. While higher density can boost durability and feel, it’s not always worth a premium if your needs are modest. Trust your instincts and weigh the benefits against the cost—sometimes, it’s better to have a little less than to pay a fortune for something that’s just “nice to have.” Make sure you’re getting the best bang for your buck.