To deacidify cellulose foundations, you can use chemical neutralization methods like applying alkaline solutions such as calcium hydroxide or sodium bicarbonate to raise the pH. Lithium-based agents and mineral additives like calcium carbonate can also stabilize acidity. Advanced techniques include microemulsion approaches for deep penetration. Proper application guarantees effective neutralization and long-term preservation. Keep in mind that monitoring pH and following best practices will help maintain material integrity; discover more about effective solutions ahead.

Key Takeaways

- Deacidification neutralizes acids in cellulose to prevent further deterioration and extend material lifespan.

- Chemical treatments use alkaline solutions like calcium carbonate or lithium compounds for effective deacidification.

- Advanced techniques involve nanoparticle dispersions stabilized with surfactants for deeper, uniform penetration.

- pH measurement before and after treatment ensures proper neutralization and monitors treatment success.

- Proper application and post-treatment care, including controlled storage, maintain long-term preservation of cellulose foundations.

Understanding Acid Degradation in Cellulose Materials

Understanding acid degradation in cellulose materials is essential because acids can cause significant deterioration over time. When acids migrate within the material, they lower the pH, creating an environment that accelerates cellulose breakdown. Accurate pH measurement helps you identify areas at risk, revealing how far acid migration has spread. This process is critical because even small shifts in pH can weaken the cellulose structure, leading to brittleness and eventual failure. Recognizing the signs of acid degradation allows you to address problems early before they cause irreversible damage. Monitoring and understanding acid migration patterns enable effective preservation strategies, ensuring your cellulose materials remain stable and durable over the long term. Additionally, proper storage in a controlled environment can significantly slow down the rate of acid-induced deterioration.

The Importance of Deacidification in Preservation

Deacidification is vital because it neutralizes acidic damage that can weaken cellulose materials over time. By addressing this issue early, you considerably extend the lifespan of your collection. Ultimately, preserving the integrity of your items depends on taking proactive deacidification steps. Incorporating preventative storage techniques can further enhance the longevity of cellulose-based materials.

Neutralizing Acidic Damage

Acidic damage poses a significant threat to the longevity of cellulose-based materials, accelerating their deterioration over time. To combat this, you must focus on maintaining proper pH balance through effective acid neutralization. When acids build up, they weaken cellulose fibers, leading to brittleness and decay. Deacidification treatments work by introducing alkaline substances that neutralize these acids, restoring the material’s stability. By carefully controlling acid levels, you prevent further damage and preserve the integrity of your artifact. Neutralizing acidic damage not only halts ongoing deterioration but also creates a more stable environment, making future conservation efforts more effective. Additionally, understanding the conservation techniques used in preserving cellulose foundations can enhance the longevity of your artifacts. Remember, timely intervention with proper deacidification techniques is essential to safeguard cellulose foundations for the long term.

Extending Material Longevity

By actively addressing acidity through deacidification, you can substantially extend the lifespan of cellulose-based materials. Regular acidity measurement helps you identify when materials are at risk of deterioration, allowing timely intervention. Proper deacidification treatments neutralize existing acids and add a buffering agent, which slows future acid formation. Ensuring treatment safety is essential; using proven methods minimizes risks to the material’s integrity while maximizing effectiveness. When you accurately assess acidity levels, you prevent unnecessary treatments that could damage the material. This proactive approach preserves the material’s structural and aesthetic qualities longer, saving you money and effort over time. Understanding color accuracy and its impact on visual quality can further enhance the preservation process. Ultimately, thoughtful deacidification extends the useful life of your collection, ensuring its preservation for future generations.

Chemical Methods of Neutralizing Acids

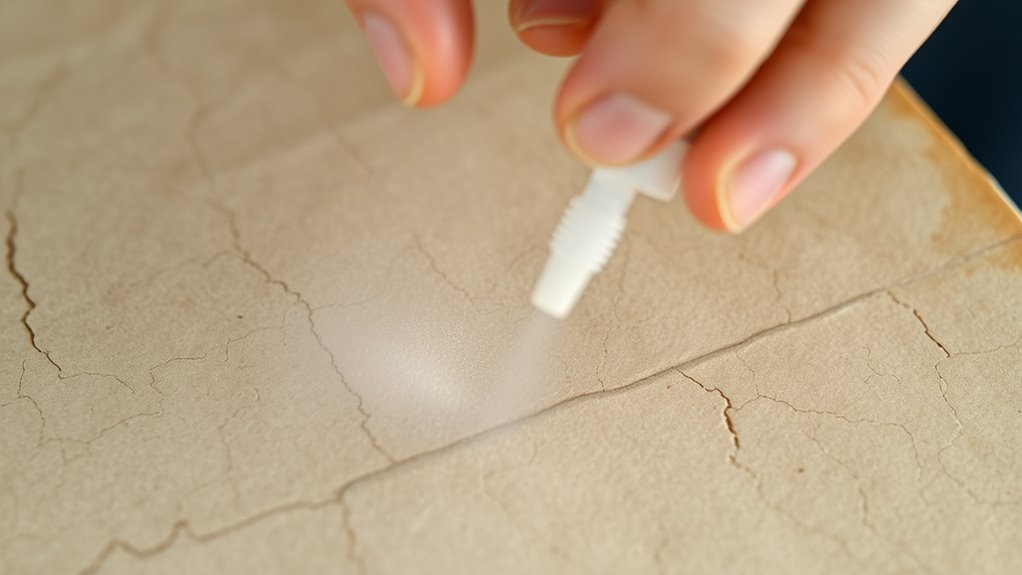

Chemical methods of neutralizing acids involve applying alkaline solutions directly to the cellulose material to counteract acidity. To guarantee effective treatment, you must carefully measure the pH of the material before and after application. Proper pH measurement helps confirm that acidity is neutralized without overcorrecting, which can weaken the material. When handling alkaline solutions, chemical safety is paramount—use gloves, goggles, and proper ventilation. You might consider using calcium hydroxide or sodium bicarbonate solutions, depending on the extent of acidity. Always apply solutions gradually and monitor pH levels closely. Keep these key points in mind:

- Precise pH measurement guides your treatment process

- Use appropriate protective gear for chemical safety

- Select the right alkaline solution for your material

- Avoid overneutralization to prevent damage

- Necessary cookies ensure the basic functionality of the treatment process.

Buffered Treatments and Their Role in Stabilization

Buffered treatments use agents that maintain a stable pH level, helping to neutralize acids and prevent further deterioration. Their effectiveness depends on selecting the right buffering agents for the specific cellulose foundation. By stabilizing pH, these treatments markedly enhance the long-term preservation of delicate materials. Incorporating leadership skills such as strategic planning and decision-making can optimize treatment protocols and improve conservation outcomes.

Buffering Agent Effectiveness

Buffering agents play an essential role in stabilizing cellulose foundations during deacidification treatments. Their effectiveness hinges on proper pH buffering, which maintains a neutral environment and prevents acidity from reestablishing. To guarantee optimal performance, the agent’s stability over time is indispensable, as degradation can reduce its buffering capacity. When selecting a buffering agent, consider these factors:

- The pH buffering range suited to the material’s needs

- Chemical stability under treatment conditions

- Compatibility with existing conservation materials

- Longevity and resistance to environmental changes

- Forsale 100 should also be considered when sourcing quality buffering agents to ensure consistency and purity.

Ph Stabilization Benefits

Maintaining a stable pH environment is essential for preserving the integrity of cellulose foundations during deacidification. Buffered treatments help achieve this by stabilizing pH levels, preventing acid catalysts from accelerating deterioration. Regular pH measurement allows you to monitor the effectiveness of the treatment, ensuring the foundation remains within the ideal neutral or slightly alkaline range. When acid catalysts are present, they can promote further acidification, so stabilizing pH minimizes this risk. By controlling pH, you reduce the likelihood of acid hydrolysis, which weakens cellulose fibers over time. Buffered treatments effectively neutralize residual acids and create a protective environment that maintains long-term stability, safeguarding your foundation’s structural and chemical integrity against ongoing acidification. Additionally, understanding the safety of electric heated mattress pads can inform how to incorporate safe electrical practices in treatment environments.

Applying Lithium-Based Deacidification Agents

Applying lithium-based deacidification agents involves carefully introducing a solution containing lithium compounds into the cellulose substrate to neutralize acids and stabilize the material. Lithium salts penetrate the fibers, effectively reducing acidity and preventing further deterioration. This method enhances treatment efficacy, ensuring long-lasting preservation. When applying these agents, consider the following:

Lithium deacidification neutralizes acids, stabilizing cellulose for long-lasting preservation.

- Proper concentration of lithium salts for ideal results

- Uniform distribution to prevent uneven treatment

- Compatibility with existing conservation materials

- Monitoring acid levels post-treatment to assess success

- Selecting appropriate deacidification techniques based on the specific condition of the cellulose objects

Using lithium-based solutions offers a reversible and non-invasive option for deacidification. This approach is especially useful for fragile or valuable cellulose objects, where precision is key. Overall, it provides a dependable way to extend the lifespan of cellulose foundations.

The Use of Calcium Carbonate and Other Mineral Additives

Calcium carbonate and other mineral additives are commonly incorporated into deacidification treatments to neutralize acids within cellulose substrates effectively. Calcium carbonate applications work by buffering acidity and stabilizing the pH, preventing further deterioration. These mineral additive benefits include their relative stability, low solubility, and compatibility with various materials, making them suitable for long-term preservation. When applied correctly, calcium carbonate can penetrate the fibers, providing localized neutralization of acids and reducing the risk of acid migration. Other mineral additives, such as magnesium oxide or calcium hydroxide, may be used in specific contexts to complement calcium carbonate’s effects. Additionally, HEPA filtration can be employed during treatment processes to control airborne particulates and ensure a clean environment. Overall, mineral additives offer a practical, environmentally friendly approach to maintaining the structural integrity of cellulose-based artifacts while minimizing potential damage caused by acidity.

Microemulsion Techniques for Deep Penetration

Microemulsion techniques have emerged as an effective method for delivering deacidification agents deep into cellulose substrates. By using nanoparticle dispersions stabilized with surfactants, you can enhance penetration and uniform distribution within the material. These microemulsions facilitate the transport of active agents, reaching areas that traditional methods might miss. Surfactant stabilization prevents nanoparticle aggregation, ensuring consistent performance. This approach minimizes surface tension, allowing microemulsions to infiltrate porous structures efficiently. You benefit from improved deacidification depth and reduced treatment times. Additionally, the small droplet size of microemulsions enables better control over agent delivery, reducing the risk of surface residue. Overall, this technique offers a promising way to protect cellulose foundations from acid deterioration through deep and effective treatment.

Evaluating the Effectiveness of Different Treatments

Evaluating the effectiveness of different deacidification treatments is essential to determine which methods best preserve cellulose foundations. You should regularly perform pH measurement before and after treatment to assess acid neutralization. Stable, elevated pH levels indicate successful deacidification, helping to prevent further deterioration. Additionally, monitoring treatment durability involves testing the cellulose’s condition over time, ensuring the treatment remains effective. You can conduct accelerated aging tests or periodic re-evaluations to verify long-term stability. Comparing pH measurements and durability results across various treatments allows you to identify the most effective approach. This process guarantees that your preservation efforts maintain the cellulose’s integrity and prolong its lifespan, making informed decisions about treatment options based on measurable outcomes.

Best Practices for Applying Deacidification Solutions

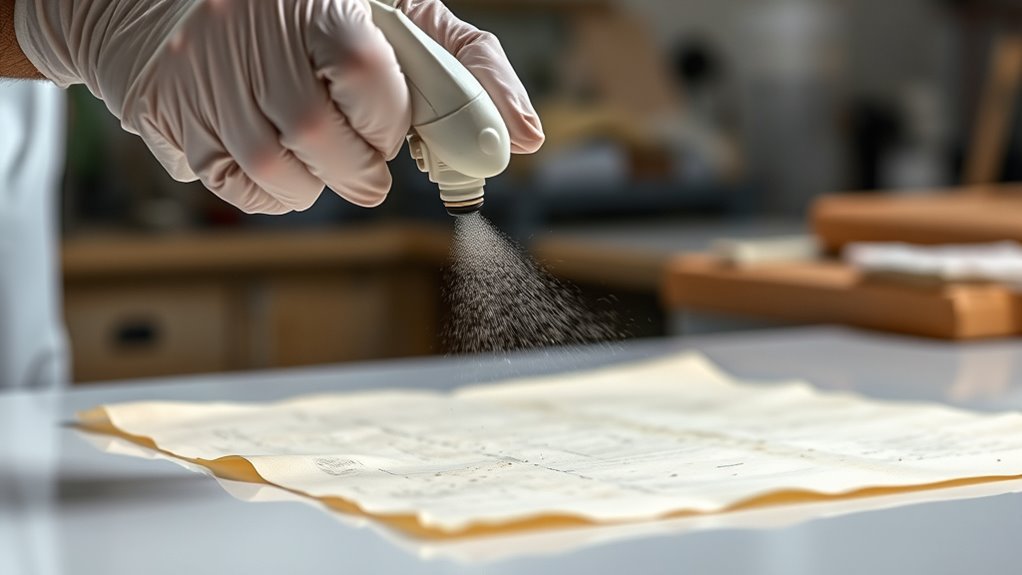

Proper application techniques are essential to ensuring deacidification solutions effectively neutralize acids and protect cellulose foundations. You should carefully monitor pH measurement during treatment to confirm neutralization levels and avoid over-treatment. Consistent application methods, such as even spray or brush techniques, help ensure uniform coverage. Consider the storage environments where treated materials will reside; stable, climate-controlled spaces prevent re-acidification. Before applying, verify the solution’s concentration and follow manufacturer instructions precisely. Use protective gear to prevent contamination and ensure safety. Regularly check the pH levels throughout the process to gauge progress. Proper preparation and adherence to these best practices will maximize treatment effectiveness and extend the longevity of your cellulose foundations.

Frequently Asked Questions

How Long Do Deacidification Treatments Typically Last?

You’re wondering how long deacidification treatments last, right? Generally, longevity estimates range from 20 to 50 years, but preservation factors like paper type, storage conditions, and treatment quality influence this. Properly applied, treatments can effectively neutralize acids and slow deterioration. Keep in mind, ongoing monitoring and maintenance can extend their effectiveness, ensuring your cellulose foundation stays stable and preserved for decades to come.

Are Deacidification Methods Safe for All Cellulose-Based Materials?

You might be surprised to learn that deacidification methods are generally safe for most cellulose-based materials, but their chemical safety and material compatibility vary. While over 90% of treatments are considered safe, some materials can react differently, risking damage. It’s essential to evaluate each case carefully, ensuring the chosen method aligns with the specific material’s properties, to prevent unintended harm and preserve the integrity of your collection.

What Are the Potential Side Effects of Chemical Deacidification?

You might notice potential side effects from chemical deacidification, such as residual chemical residues left on the material, which could cause long-term issues. Additionally, some treatments may lead to material discoloration, affecting the appearance and integrity of the cellulose-based foundation. It is crucial to carefully consider these risks, as improper application or unsuitable chemicals can compromise the material’s stability and aesthetic over time.

Can Deacidification Treatments Be Reversed or Removed Later?

Think of deacidification treatments as a tattoo—they’re meant to be permanent, but sometimes you wonder if they can be erased. Reversibility concerns come into play because removing these treatments isn’t always straightforward; it depends on the materials used and how deeply they penetrated. Removal techniques, like chemical washes or mechanical methods, exist but can risk damaging the original material. Always consult a conservation expert before attempting any removal.

How Do Environmental Conditions Affect Deacidification Effectiveness?

You might wonder how environmental conditions impact deacidification’s effectiveness. Humidity impact is significant because high moisture levels can accelerate acid production, reducing treatment longevity. Temperature influence also plays a role; elevated temperatures can speed up chemical reactions, potentially diminishing deacidification results over time. By controlling humidity and temperature, you guarantee the treatment remains effective longer, helping preserve cellulose foundations and preventing acid-related deterioration.

Conclusion

By understanding acid degradation and choosing the right deacidification methods, you can guarantee your cellulose materials stand the test of time. Applying proper treatments isn’t just a shot in the dark—you’re laying a solid foundation for preservation. Remember, it’s better to nip problems in the bud before they grow out of hand. With careful application and the right techniques, you’ll keep your artifacts healthy and vibrant for generations to come.