Hand-knotted rugs generally have a higher carbon footprint than machine-made ones due to longer production times, greater energy use, and transportation emissions from distant areas. Manual craftsmanship and intricate dyeing increase energy and labor demands, while transportation adds to environmental impact. However, they often last longer and can be recycled more sustainably. If you want to understand how these factors really compare, there’s more to uncover below.

Key Takeaways

- Hand-knotted rugs have higher carbon footprints due to labor-intensive processes and longer production times.

- Machine-made rugs typically consume less energy per unit, reducing overall carbon emissions.

- The long-distance transportation of hand-knotted rugs increases their transportation-related carbon footprint.

- Natural dyes and sustainable sourcing in hand-knotted rugs lower environmental impact during production.

- Durability and the potential for recycling natural fiber rugs help mitigate their long-term environmental effects.

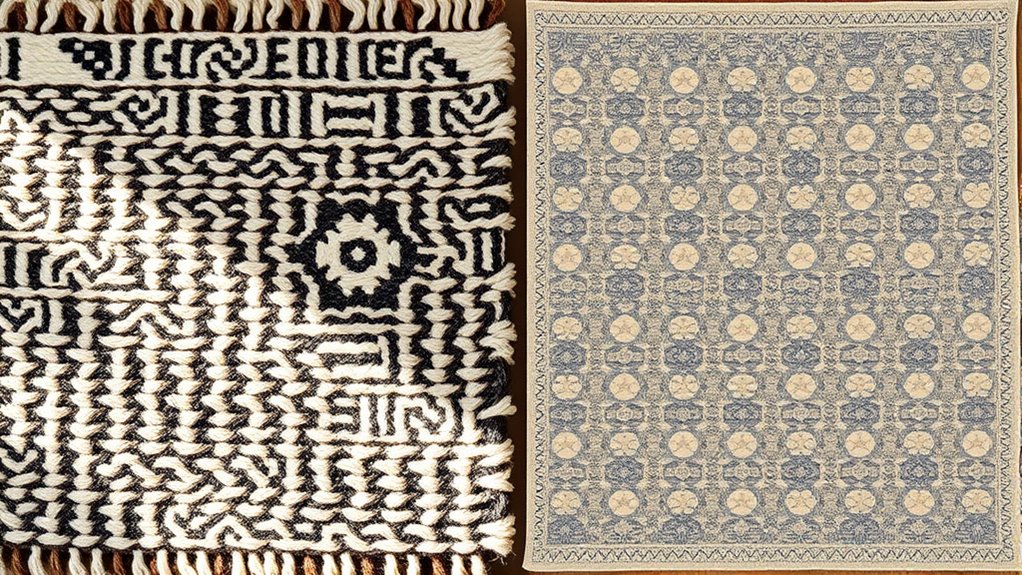

Manufacturing Processes and Material Use

When comparing hand-knotted and machine-made rugs, the manufacturing process and materials used play a crucial role in their environmental impact. Hand-knotted rugs often utilize natural dyes, employing traditional dyeing techniques that reduce chemical waste and pollution. This careful approach emphasizes sustainable sourcing practices for fibers like wool or silk, which are often ethically harvested. In contrast, machine-made rugs frequently rely on synthetic dyes, which involve chemical-intensive dyeing methods that can harm waterways and ecosystems. The sourcing practices for machine-made rugs may also favor cheaper, mass-produced fibers, sometimes sourced unethically. Additionally, the dyeing techniques employed significantly influence the ecological footprint of each rug, with natural dyeing generally being more environmentally friendly. Overall, the differences in dyeing techniques and sourcing practices substantially influence each rug’s ecological footprint, making hand-knotted rugs generally more eco-friendly due to their reliance on natural materials and sustainable processes.

Energy Consumption During Production

You’ll notice that machine-made rugs often use less energy per unit due to more efficient machinery, whereas hand-knotted rugs require significant manual effort. Production times also vary, with machine manufacturing typically completing rugs faster, reducing overall energy use. Understanding these differences helps you see how machinery efficiency levels and process durations impact the environmental footprint. Additionally, tuning techniques for vehicles like Honda models demonstrate how optimized processes can lead to improved performance and efficiency.

Manufacturing Energy Use

Manufacturing energy use plays a significant role in the overall carbon footprint of rugs, with notable differences between hand-knotted and machine-made processes. Hand-knotting often involves less machinery energy but requires extensive manual labor, especially for intricate designs. Machine-made rugs, on the other hand, consume more energy during production, driven by automated looms and dyeing techniques. Higher design complexity in machine-made rugs can increase energy consumption due to longer processing times and advanced equipment. Additionally, color accuracy influences the amount of energy required for dyeing and finishing processes, further impacting overall energy use.

Machinery Efficiency Levels

Machinery efficiency levels considerably influence the energy consumption of rug production. Well-calibrated machines operate smoothly, reducing unnecessary energy use and waste. Regular equipment maintenance ensures machines run at peak performance, preventing inefficiencies caused by worn parts or misalignment. When machines are properly calibrated, they use the right amount of energy for each task, avoiding excess power consumption. Conversely, neglected maintenance can lead to higher energy demands, increased wear and tear, and longer production times. Improving machinery efficiency through routine calibration and maintenance directly lowers the energy footprint. Additionally, energy-saving techniques can further optimize power use in manufacturing. As a result, you minimize environmental impact and reduce costs. Maintaining high efficiency levels isn’t just about productivity; it’s a vital step toward sustainable manufacturing practices that respect the planet.

Production Time Differences

While hand-knotted rugs typically take longer to produce than machine-made ones, this extended production time often results in higher energy consumption overall. The longer process involves meticulous hand-knotting, which is labor-intensive and time-consuming. Additionally, dyeing techniques used for hand-knotted rugs often require multiple steps and careful handling to achieve vibrant colors and intricate designs, increasing energy use. The design complexity of hand-knotted rugs also plays a role; more complex patterns require more knots and detailed work, lengthening production time and energy expenditure. In contrast, machine-made rugs benefit from automated processes that considerably reduce production time and energy consumption. Therefore, the longer, more intricate production process of hand-knotted rugs contributes to a higher overall carbon footprint related to energy use. Natural materials used in hand-knotting also require sustainable sourcing practices, which can further impact environmental considerations.

Labor Intensity and Craftsmanship

You’ll notice that hand-knotted rugs require significant manual labor, involving highly skilled artisans who spend hours, sometimes days, crafting each piece. This craftsmanship demands a high skill level and considerable time, making these rugs more labor-intensive than machine-made alternatives. Understanding this difference helps you appreciate the craftsmanship behind each rug and its environmental impact. Additionally, the detailed profile provided by 16PF assessments reflects the nuanced skills and personality traits of artisans, highlighting the complexity behind traditional craftsmanship.

Manual Labor Requirements

Manual labor plays a crucial role in the creation of hand-knotted rugs, demanding a high level of skill, patience, and physical effort from artisans. The process relies heavily on hand labor, where each knot is meticulously tied by skilled craftspersons, making craftsmanship skills essential. This intensive work involves repetitive motions, precise tension, and careful attention to detail, which can take weeks or months to complete a single rug. Your involvement in this process means the labor intensity is high, reflecting the dedication and expertise required. Unlike machine-made rugs, which minimize manual input, hand-knotted rugs depend on human effort, directly impacting the overall carbon footprint. This manual labor not only preserves traditional techniques but also contributes considerably to the rug’s uniqueness and quality. Additionally, the craftsmanship process often results in a more sustainable product, as it emphasizes quality over mass production.

Skill Level and Time

Creating a hand-knotted rug demands a high level of skill and significant time investment, setting it apart from machine-made alternatives. With handmade artistry, artisans meticulously knot each thread, showcasing craftsmanship and attention to detail. This process can take weeks or even months, depending on the rug’s size and complexity. Unlike machine precision, which produces rugs quickly and uniformly, hand-knotting relies on the artisan’s expertise, resulting in unique, intricate designs. The time and skill required not only enhance the rug’s artistry but also increase its environmental footprint, as more labor and resources are involved. Additionally, psychological research indicates that engaging in meticulous craftsmanship like hand-knotting can promote mindfulness and personal fulfillment. Your choice between handmade and machine-made rugs ultimately reflects a balance between craftsmanship, time commitment, and ecological considerations.

Transport and Supply Chain Impacts

Transport and supply chain impacts markedly influence the overall carbon footprint of rugs, with differences between hand-knotted and machine-made products often reflecting their sourcing and distribution methods. Hand-knotted rugs typically originate from distant regions like Persia or India, resulting in higher shipping emissions due to long-distance transport. Machine-made rugs, often produced locally or regionally, benefit from shorter distribution logistics, reducing their transportation footprint. Efficient logistics and transportation choices substantially lower overall emissions. Here’s a comparison:

| Aspect | Hand-Knotted Rugs | Machine-Made Rugs |

|---|---|---|

| Sourcing Location | Distant regions (e.g., Persia, India) | Local or regional factories |

| Shipping Emissions | Higher due to long-distance shipping | Lower, often regional distribution |

| Distribution Logistics | Complex, international logistics | Simpler, regional or local |

| Transportation Mode | Cargo ships, long-haul trucks | Shorter routes, fewer shipments |

| Carbon Footprint Impact | Generally higher | Usually lower |

Additionally, adopting sustainable transportation methods can significantly mitigate the environmental impact of rug distribution.

Durability and Longevity of Rugs

While both hand-knotted and machine-made rugs can last for decades, their durability often depends on construction quality and usage. Hand-knotted rugs typically use superior materials and intricate dyeing techniques, which enhance their resilience over time. Proper rug maintenance, like regular cleaning and avoiding excessive moisture, helps preserve their quality and appearance. Machine-made rugs may be more uniform but can wear out faster if constructed with lower-quality fibers or dyes that fade quickly. The durability also hinges on the type of dyes used—natural dyes tend to fade more gracefully, extending the rug’s lifespan. Additionally, rug construction techniques play a crucial role in ensuring longevity. Ultimately, investing in well-crafted rugs and adhering to good rug maintenance practices guarantees you get the most longevity from your purchase, reducing replacements and their associated environmental impact.

End-of-Life and Recycling Potential

When a rug reaches the end of its life, its recyclability considerably impacts its environmental footprint. Your choices for end-of-life options influence whether it becomes waste or a resource. Rugs with high recycling potential can be repurposed, reducing landfill waste and conserving resources.

Recycling rugs extends their life, reduces waste, and conserves resources—choose eco-friendly end-of-life options whenever possible.

Consider these options:

- Reusing as a base for new crafts or projects

- Donating to charities or shelters

- Recycling through specialized facilities

- Repurposing into padding or insulation

- Composting natural fiber rugs

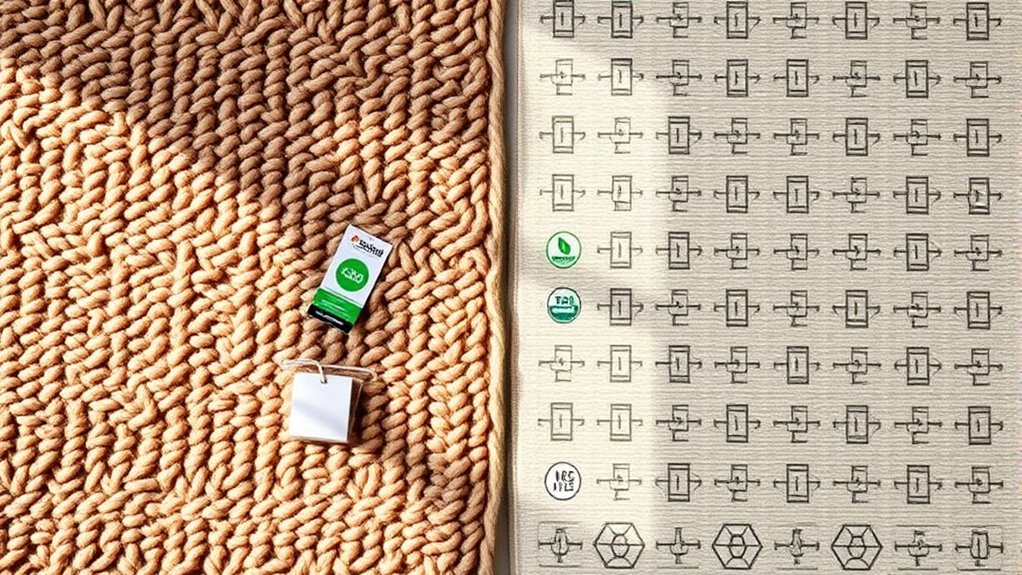

Environmental Certifications and Standards

Choosing rugs with recognized environmental certifications guarantees that their manufacturing processes meet strict sustainability standards, from raw material sourcing to production practices. Eco‑label standards set clear criteria for eco-friendly materials, energy efficiency, and waste management, ensuring the product’s environmental integrity. Certification processes typically involve thorough audits and assessments, verifying compliance with these standards. When a rug bears reputable certifications, you can trust that it minimizes environmental impact throughout its lifecycle. These certifications often address issues like chemical usage, water conservation, and fair labor practices. By selecting rugs with valid eco‑labels, you support sustainable manufacturing and help reduce your overall carbon footprint. Knowing the certification process assures you that the product has undergone rigorous evaluation, aligning your choices with environmentally responsible practices.

Consumer Choices and Sustainable Practices

Your choices as a consumer have a direct impact on promoting sustainability in the rug industry. By selecting rugs with cultural significance and high aesthetic appeal, you support artisans and eco-friendly practices. To make sustainable choices, consider:

- Opting for hand-knotted rugs made with natural fibers

- Prioritizing rugs from certified sustainable sources

- Researching the cultural background to appreciate craftsmanship

- Choosing designs that align with eco-conscious values

- Supporting brands committed to low-impact production

Your decisions influence market trends, encouraging manufacturers to adopt greener practices. Recognizing the cultural significance of traditional techniques and the aesthetic appeal of well-crafted rugs helps you make informed, eco-friendly purchases. This mindful approach fosters a more sustainable rug industry, reducing carbon footprints and preserving craftsmanship for future generations.

Frequently Asked Questions

How Does the Carbon Footprint of Rug Disposal Compare?

When you dispose of rugs, consider recycling options to reduce environmental impact. Hand-knotted rugs, often made from natural fibers, are more biodegradable and easier to recycle, lowering their landfill impact. Machine-made rugs may contain synthetic materials that take longer to break down and are harder to recycle, increasing landfill impact. By choosing eco-friendly disposal methods, you help minimize the carbon footprint associated with rug disposal and support sustainability efforts.

Are Handmade Rugs Generally More Eco-Friendly Than Machine-Made?

Think of handmade rugs as a symphony of artisanal craftsmanship, woven from natural materials. You’ll find they’re generally more eco-friendly than machine-made rugs, because they often use sustainable fibers and involve less energy-intensive processes. By choosing handcrafted rugs, you support traditional techniques and reduce environmental impact, making your home not only stylish but also a conscious, eco-friendly space.

What Is the Impact of Dyeing Processes on Environmental Footprint?

You should consider that dyeing processes considerably impact the environmental footprint. Using natural dyes reduces chemical runoff, which is harmful to ecosystems, unlike synthetic dyes that often pollute water sources. Natural dyes are biodegradable and less toxic, making them more eco-friendly. By choosing rugs dyed with natural dyes, you help lower pollution and support sustainable practices, ultimately reducing the overall environmental impact of rug production.

Do Rug Size and Design Complexity Affect Environmental Impact?

Think of your rug as a garden—bigger and more intricate designs are like sprawling, detailed landscapes. Larger rug sizes demand more materials and energy, increasing environmental impact. Similarly, complex designs require extra dyeing and craftsmanship, which also raises the carbon footprint. So, when choosing a rug, consider how size and design complexity can grow your environmental footprint, and opt for simpler, smaller options to reduce your ecological impact.

How Do Consumer Maintenance Habits Influence Overall Sustainability?

Your maintenance habits greatly impact a rug’s sustainability. If you adopt eco-friendly cleaning routines, like using natural cleaners and avoiding harsh chemicals, you reduce environmental harm. Recycling practices, such as repurposing or donating old rugs instead of discarding them, also lower waste. By being mindful of these habits, you extend your rug’s lifespan and lessen its overall carbon footprint, making your choices more sustainable for the planet.

Conclusion

Ultimately, choosing between hand-knotted and machine-made rugs depends on your values and priorities. Will you prioritize craftsmanship and durability, or focus on efficiency and lower immediate impact? Picture the intricate detail of a hand-knotted rug versus the streamlined process of a machine-made one—both tell a story. By considering their environmental footprints, you can make a conscious decision that aligns with your sustainability goals. Isn’t your home a reflection of your values?